Analyzing Aerospace Engine Oil Debris

Aircraft engines have a high cost of failure. To keep them running smoothly, operators routinely analyze oil debris to note where potential problems may arise and make repairs as needed. Our aerospace engine manufacturer client was looking to offer a new oil debris analysis service to their customers. We built a desktop app to connect with desktop scanning electron microscopes to support this analysis.

Opportunity

Aircraft engines are equipped with self-contained oil systems that provide a continuous flow of oil to the engine, no matter the condition. These recirculatory systems house and distribute oil needed for cooling and lubricating every moving part in the engine. Our client manufactures aircraft engines for military and commercial use. In an effort to better predict when engine parts need to be serviced or replaced, they analyze the debris found in the oil system. If all is going well, there should be little metal debris in the oil. Unexpected debris appearing in the oil is a strong signal that something is wrong.

Modern engines have thousands of distinct parts, but the chemical composition of the debris can give strong clues about where issues may lie. Our client wanted to develop a proprietary software product to automate this analysis and offer it as a service to their customers. The app needed to interface with new desktop scanning electron microscopes (SEMs) to present and record the results of this analysis in an accessible way to detect trends and failures in the engine parts. Previously, samples had been sent to a lab and it could take weeks to receive results. They engaged SEP to create a hybrid web-desktop app.

Solution

We began our engagement with a collaborative product discovery phase to understand the oil analysis process. After doing design studio sessions with users of the old system, we created wireframes and then high fidelity screens to design and test the flow of the new app. Once we received the feedback from the users, we were able to create a proof of concept for our client. We collaboratively brought the app to life as a series of screens that simulated the UI and interaction design. This prototype helped our client better engage with their customers and deepen understanding of their needs. To speed up development, we interfaced with our client’s vendor, the maker of the SEM. They helped us build the right connections for our app to communicate with the SEM and with proprietary material classification algorithms.

We added features to allow the user to configure the microscope to scan a specific set of samples (based on where they were collected from in the engine). Customizable reporting was implemented to support targeted maintenance decisions. We also created functionality that allows the user to go back and manually rescan complex particles. We helped our client secure a key customer by adding further material classification and reporting capabilities. We did regular live demos for our stakeholders at the SEM we hosted at our office. Having this complex piece of equipment on site was crucial to building the app. It provided the realistic experience needed to develop and test the software/hardware integrations.

The app runs in a web browser but is hosted locally on the user’s machine. This took some crafty synchronization work as the SEM has a state (scanning or not) and the web is stateless.

Results

The app we built automates the oil debris analysis process, which previously had to be sent off to a lab. The new process provides real-time results and cuts out weeks of wait time, giving engine maintenance personnel crucial information for making decisions about when engine parts need to be replaced or serviced. This application is a potent tool for improving safety and reducing aircraft maintenance costs. The app is at the heart of our client’s plan to provide new maintenance services for their customers. In effect, it will also provide our client with a wider array of real-life engine performance data from across the world.

Recent Case Studies

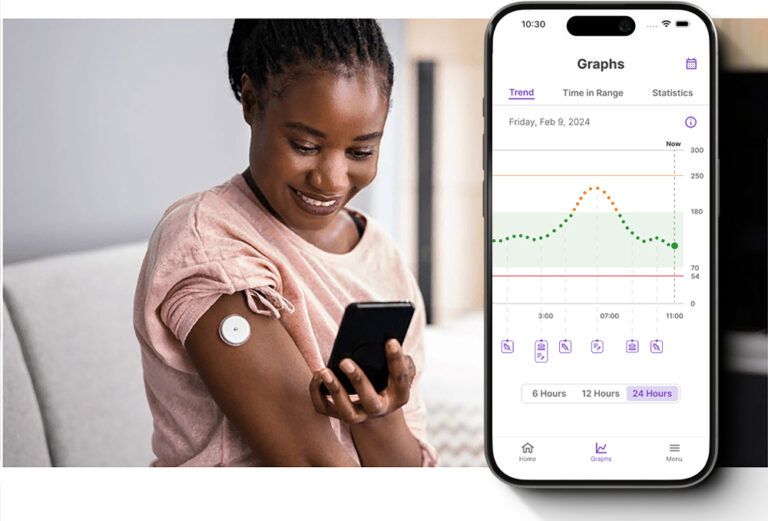

Empowering Patients with a Groundbreaking User-Friendly CGM

Crafting Luxury Smart Home Solutions: The Power of Tech-Enabled Innovation

Let’s develop something special.

Reach out today to talk about how we can work together to shake up your industry.