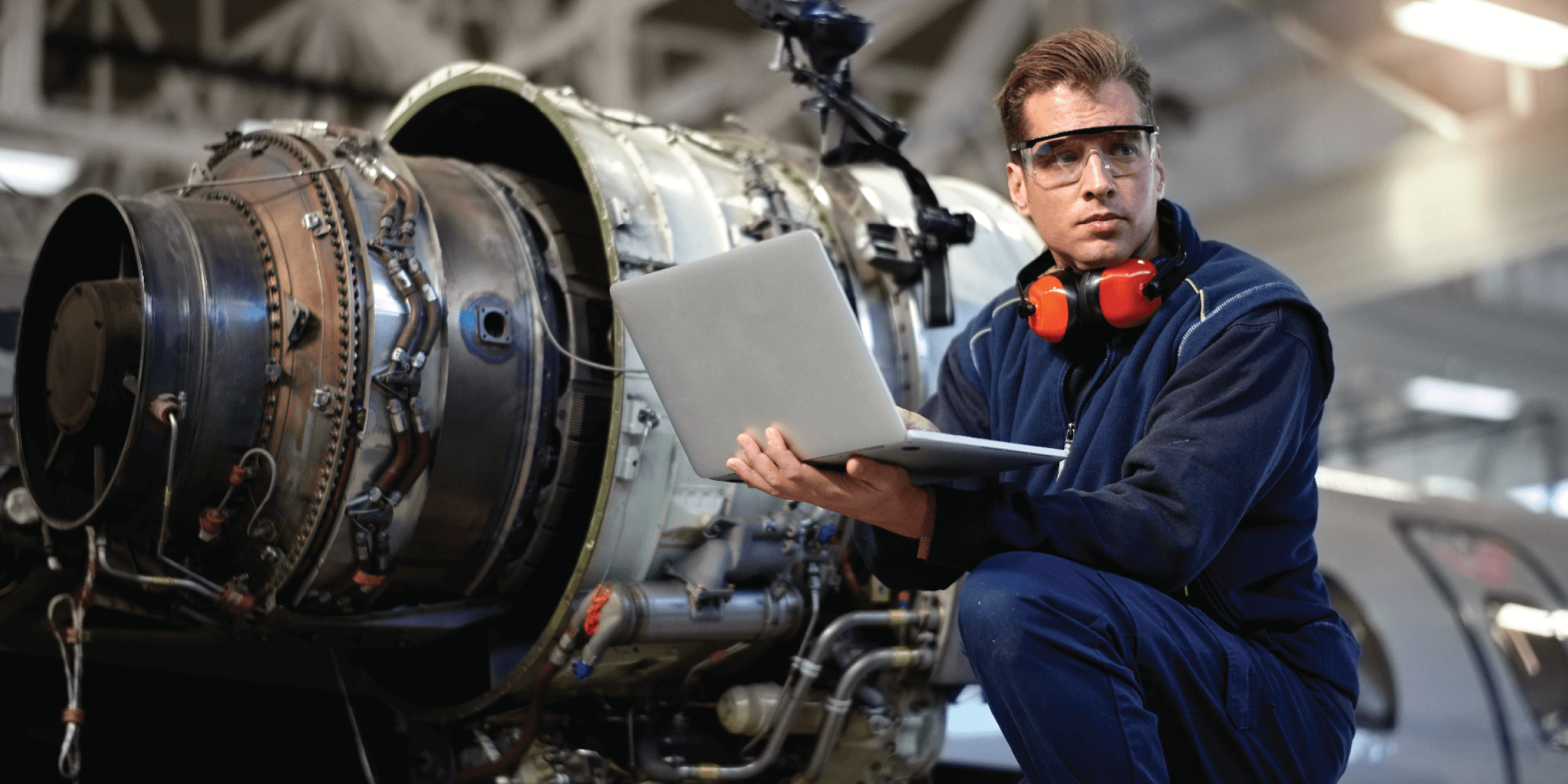

Paving the Way for Safer Skies

We worked with our aerospace and defense client over the course of 25+ years to update and add new features to their aircraft ground station controls desktop software.

The desktop app we built empowers users to make better decisions about their engines—preventing costly repairs and potential catastrophes.

What We Did

Tech Stack

Opportunity

Modern aircraft engines are incredibly complex systems with a very high cost of failure. In order to operate safely and efficiently, they require careful and intelligent monitoring. Our client, an aerospace engine manufacturer, uses ground stations to track the health of their engines, which power both military and commercial airline fleets in 100+ countries across the world. Ground stations are ruggedized laptops on the ground with software applications that receive data from the planes’ airborne engine control and monitoring systems. Maintenance personnel analyze the data from the flights to diagnose and predict potential issues and drive decisions about repairs.

Our client (and their customers) depend on ground stations to keep planes in the air. The ground stations were built on legacy technology that no longer met their needs. Our client also needed to make vital changes in order to support their new business model, where their customers pay to lease engines per flight hour, instead of for time and materials. This new business model wasn’t just a fad; getting it right determined the viability of their military partnerships, a huge part of their business.

Over the course of 25+ years, they engaged SEP to make updates to the ground station software and later to add features to support these new business needs.

Solution

In that time, we worked on 10 different engine types for our client, or nearly 50% of their engine programs. Initially, we helped our client convert their ground station desktop application from an older technology to a new one using C++ and C#. In other phases, we added functionality to the diagnostic area of the software. The software needed to interface with the aircraft’s flight recorder, or black box, to pull necessary information about engine performance.

Coupled with our traditional engineering background, the deep understanding we gained for our client’s domain meant that they entrusted us to develop the actual criteria for the engine diagnostics.

We also created our client’s first ever prognostic software. This software was the first to look to the future and predict potential issues, rather than diagnose issues that had already happened.

We completed software verification and testing for the app on our local testbed, without taking up client testing resources. We tested in support of engine qualification and certification level verification to meet stringent FAA and DOD (DO-178B Level D and DO-278A) regulations.

Our client looked to us to fully manage the software development lifecycle. We also properly secured and managed our client’s export controlled data.

Results

The updates we made to the ground station software supported our client’s move to the new per flight hour business model. The ground station data helps our client monitor supply chain needs, verify the engines are used optimally, and remain ready to execute their customers needs.

The ground station software empowers our client to make crucial engine utilization decisions, preventing costly, unnecessary repairs or preempting potential catastrophic engine failures.

Our work together ensures that planes using our client’s engines fly with fewer engine incidents. As a result, our client was globally recognized for their efforts keeping planes safe during military war-time operations.

Recent Case Studies

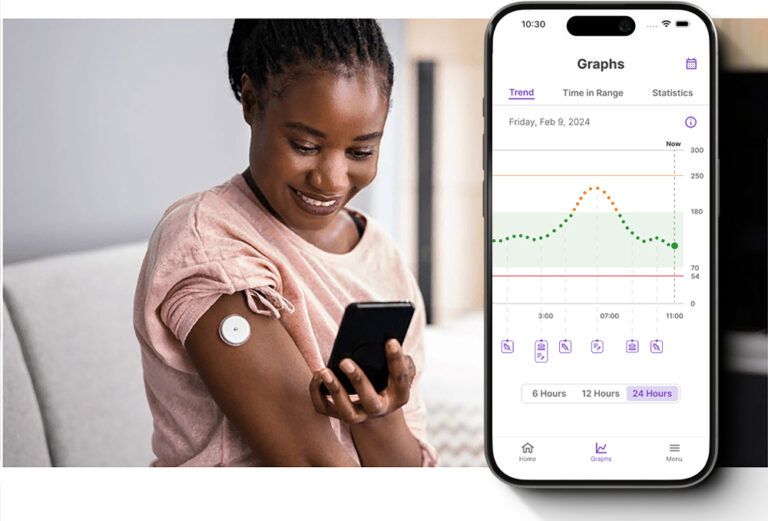

Empowering Patients with a Groundbreaking User-Friendly CGM

Crafting Luxury Smart Home Solutions: The Power of Tech-Enabled Innovation

Let’s develop something special.

Reach out today to talk about how we can work together to shake up your industry.