Automating Engine Inspections

Our aerospace and defense client needed help automating their engine inspection process while leveling up their Cloud capabilities.

We built a tool in the Cloud that inspects engine parts automatically. This solution improves the accuracy of measurements and decisions, reduces costs, and gets aircraft back in the air faster.

Opportunity

Our aerospace and defense client needed help automating their engine inspection process while leveling up their Cloud capabilities. Before our engagement, they manually inspected engine parts to determine whether they required maintenance. This involved recording information by hand, which led to mistakes and wasted time.

Our client wanted to show their government customer how automation and the web interface could be securely implemented in the Cloud. This would eliminate the need for paper records, and allow them to:

- Reduce human error

- Save time

- Stop shipping physical copies of records

- Collect and analyze engine data

- Decrease software licensing costs

They engaged us to build this tool based on our decades-long relationship, our aerospace domain expertise, and our experience in Cloud development.

Solution

Our client had a clear vision for their product, but needed guidance on how to strategically execute it. To empower them to make the right decisions, we began with a Discovery workshop. We worked through our riskiest assumptions, validated what needed to be built, built low and high fidelity prototypes, and crafted a roadmap of what the system could look like.

Next, we began developing the first release of the product. Our goal was to build a minimum viable product (MVP) that would automate the inspection process and enable our client to add more features as needed.

Our MVP automates the use of a third-party software package to analyze files from a blue light scanner. It then produces and displays relevant outputs, including part measurements and images. Engine analysts can quickly use the measurements to determine whether a part is ready to return to flight or requires maintenance.

This tool was the first application built in our client’s Azure Government as a part of their transition to the Cloud. This platform keeps sensitive data on U.S.-made machines and data centers. We coached our client’s IT teams through this process and helped them establish a strategy and best practices for future Cloud work.

Results

The MVP of this automated inspection tool improves accuracy of measurements and decisions, reduces human errors, facilitates transfer of information, and enables future cost savings.

We left our client feeling confident in their Cloud capabilities, equipped with guidelines for future Cloud work, and ready to serve their potential customer.

Recent Case Studies

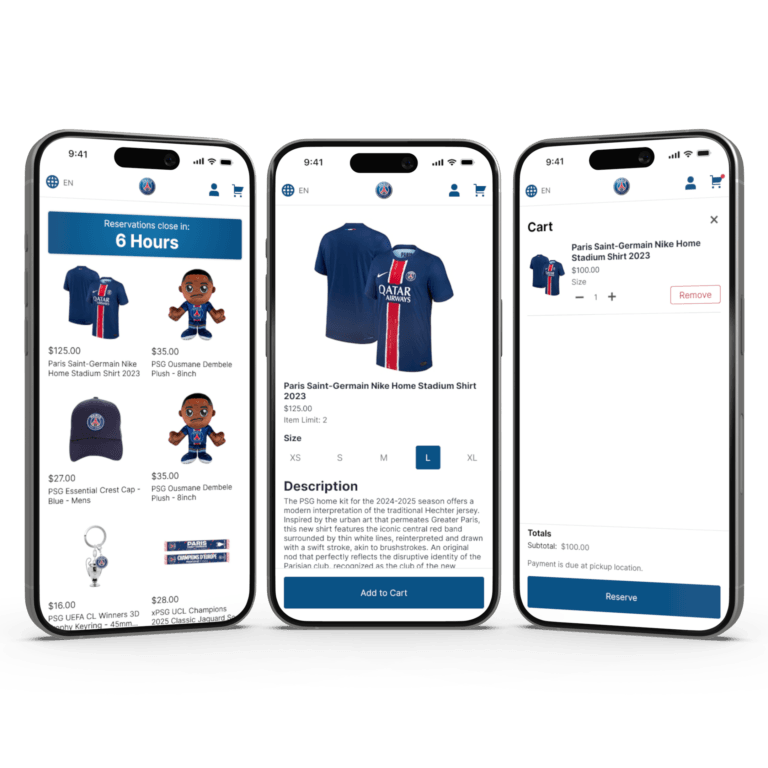

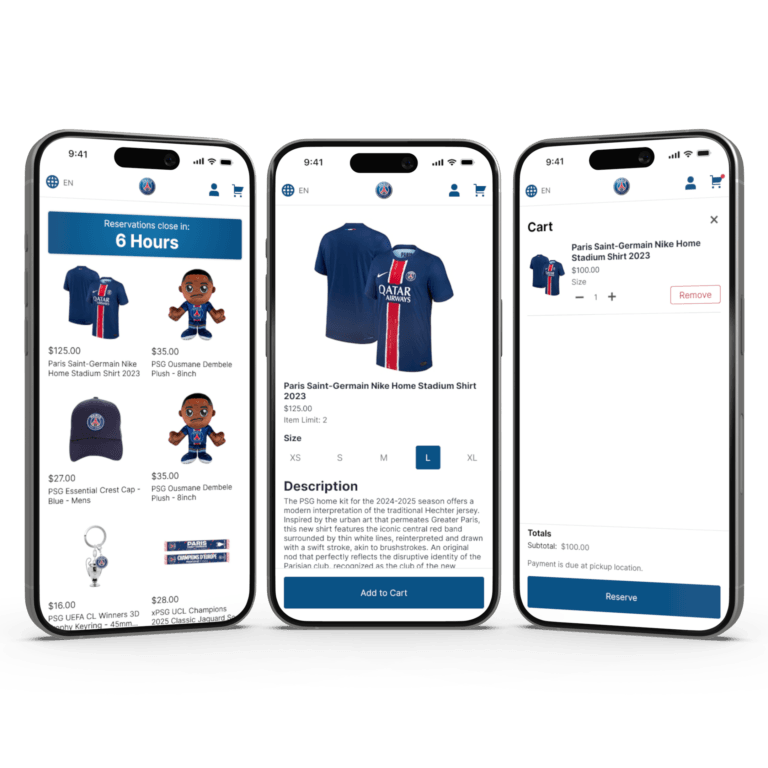

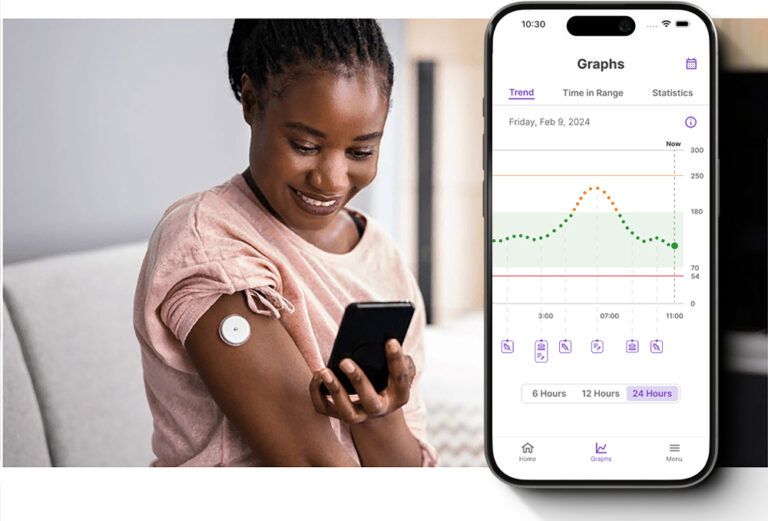

Empowering Patients with a Groundbreaking User-Friendly CGM

Crafting Luxury Smart Home Solutions: The Power of Tech-Enabled Innovation

Let’s develop something special.

Reach out today to talk about how we can work together to shake up your industry.