Visualizing Aircraft Maintenance Data

Our aerospace and defense client had amassed years’ worth of data on aircraft engine maintenance and repairs. They engaged us to convert this data into insights, with a goal of finding $1 million in savings.

We worked together to create Tableau and PowerBI visualizations and mathematical models using R. The data visualization solution far exceeded the goal of finding $1 million in savings – it revealed insights on maintenance schedules that totaled savings of over $3 million.

Opportunity

A familiar problem: you collect all the data you can about your business…how do you then turn it into usable and valuable insights?

One of our clients faced this problem. They had amassed years’ of data about the aircraft engine maintenance and repairs they do for customers. Due to the size and complexity of aircraft engines, this means a lot of information, captured primarily in Excel. Our client knew that insights were hiding in this data – potentially millions of dollars of savings and improvements. They engaged us to convert this data to those insights.

Solution

Together, we envisioned a data visualization solution to analyze maintenance and repair data. We created Tableau and PowerBI visualizations of different types of repairs, trends over time and by location, detailed views of repairs on specific engine parts, and other statistical models.

We paired up with our client’s statistics guru to create the right mathematical models using R, an open source programming language for statistical computing and creating visualizations.

The solution enables our client to see what engines meet certain maintenance requirements, so they can be sold, used, and repaired differently. These findings drove changes in preemptive maintenance schedules, which extend the life of the aircraft engines. This translates into significant savings from reduced maintenance and operation costs.

Results

This data visualization solution helped our client far exceed their goal of finding $1 million in savings. The tool made it clear that by servicing a specific part more often, they can save a huge amount of money on total engine repairs over the course of time. These savings totaled over $3 million. Huge savings like these show the value of stepping back and looking at your data differently; you never know what insights you might uncover.

Recent Case Studies

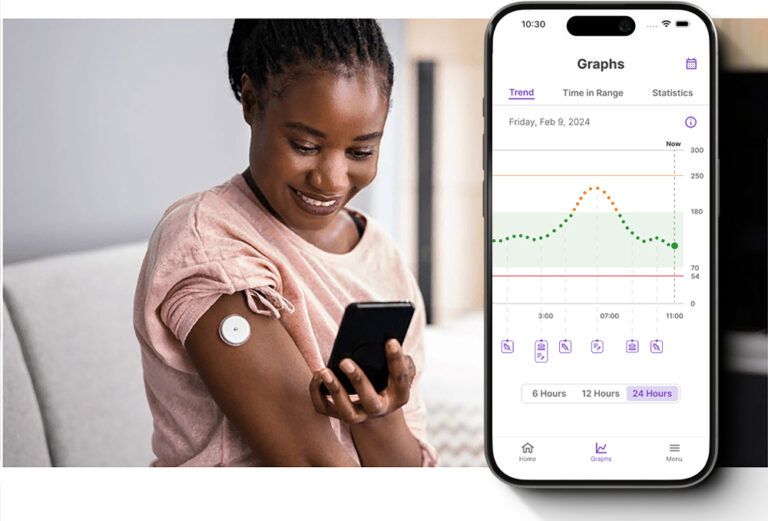

Empowering Patients with a Groundbreaking User-Friendly CGM

Crafting Luxury Smart Home Solutions: The Power of Tech-Enabled Innovation

Let’s develop something special.

Reach out today to talk about how we can work together to shake up your industry.