Optimizing Sawmill Equipment

A sawmill equipment manufacturer wanted to build an optimizer that maximizes the amount of usable lumber they can make from logs.

We worked with our client to build a prototype of the optimizer. We proved that our solution was technically feasible and set the foundation so that our customer could launch their own optimization product.

What We Did

Tech Stack

Opportunity

A global leader in sawmill equipment identified an opportunity to build their own optimizing software to pair with their sawmill equipment. If they could do it, it would give them a strategic advantage over their competition and minimize the risk of reliance on third-party tools.

They engaged us to evaluate the feasibility and cost of building a new optimizer software package.

We faced some unique challenges in building this optimizer:

- The solution needed to incorporate multiple vision technologies to detect defects in the raw material.

- The solution had to work quickly – complex computations to determine how to cut the boards needed to be done within 2 seconds.

- Uncertainty existed with how the boards would be positioned in the machine. The system took a visual snapshot of the log before it was put in place. As a result, we knew about the material conceptually, but we didn’t know exactly how it would be positioned at the time of cutting.

Solution

To determine technical feasibility, we started our engagement with a Discovery effort. This helped us reduce risk by uncovering viable paths forward and investing in shared learning. We removed the monster hiding in the riskiest assumptions through rapid prototypes and testing. We involved stakeholders from each part of the business early in the process. This was critical to understanding all risks involved and making the Discovery successful.

Using F#, we built a prototype based on images of lumber from our client. It was important to come up with a solution that would accommodate 15-25 boards per minute to meet industry demand.

We planned for all likely positions of the lumber after being grasped by the machine. This uncertainty introduced additional variables to the planning problem, each one making the problem exponentially harder to solve.

Our prototype demonstrated that we could solve the problem in under 1.25 seconds, so we felt confident we could meet the 2 second goal. Not only was our tool faster than the old one, it also produced more optimal cuts.

Once we discovered the solution was technically feasible, we started story mapping the full solution to lay out the challenges ahead. We worked with our client to split the story map into multiple future releases.

We used a low fidelity prototyping technique called UI breadboarding to ensure we included the necessary elements of the UI. This helped us make sure we considered everything we’d need to build when forecasting the cost and timeline to build the full solution.

Results

We showed that our solution was technically feasible and able to produce optimal solutions within our client’s time constraints. The new solution would enable our client to be more environmentally friendly by reducing waste.

Our work showed the value of Discovery in building the right thing, being deliberate about high and low fidelity prototyping, and including all types of stakeholders in Discovery. This effort gave our client confidence in the feasibility of the solution and an estimate of cost and timeline to build it.

We set the learning and production foundation, preparing our client to launch their own product should the third party tool become unavailable.

Recent Case Studies

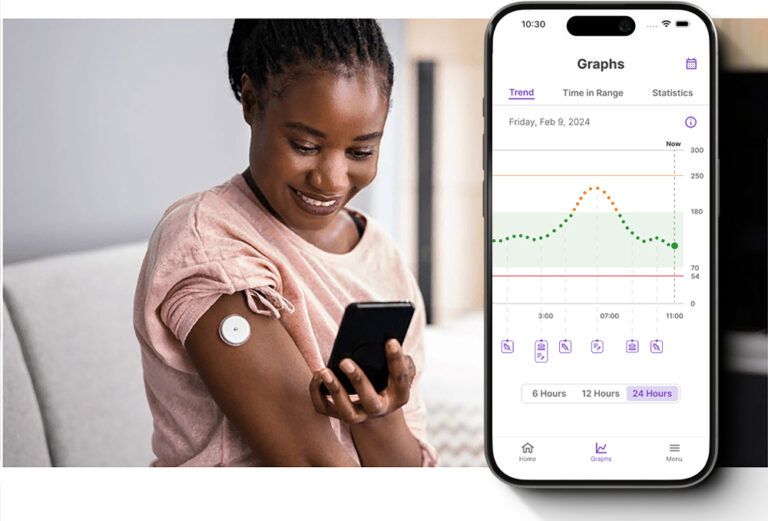

Empowering Patients with a Groundbreaking User-Friendly CGM

Crafting Luxury Smart Home Solutions: The Power of Tech-Enabled Innovation

Let’s develop something special.

Reach out today to talk about how we can work together to shake up your industry.